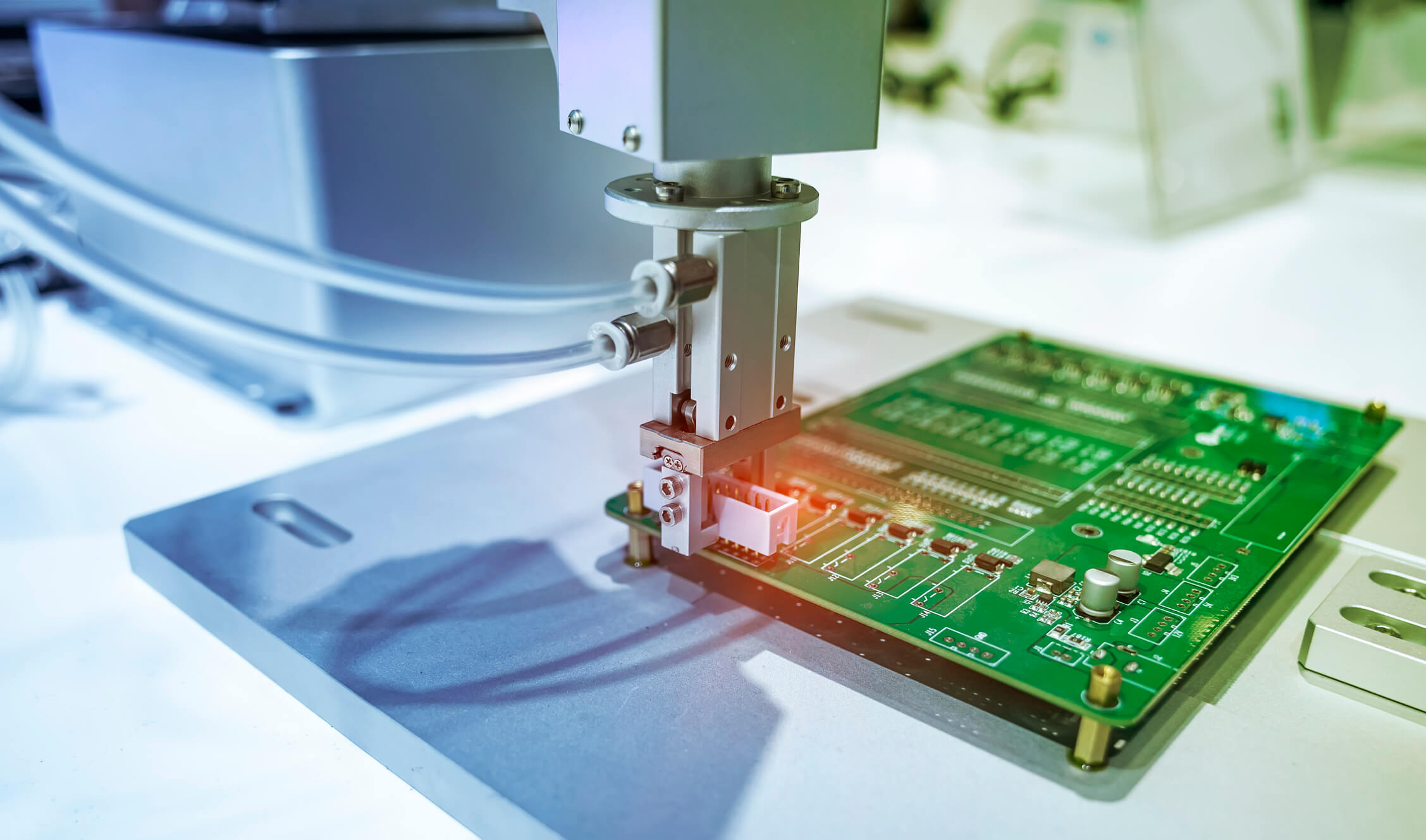

Many of today’s electronic component manufacturers are setting aggressive revenue growth targets but few have adequate internal resources to pursue direct sales strategies because of financial, hiring, or geographical limitations. The solution: drive growth through partnerships with carefully chosen channel partners.

But considerable challenges can arise when you pursue this path. Although distributors – especially large, multinational ones – possess both the ability to scale and to reach high volumes of customers, they need to know that component manufacturers are capable of holding up their end of the relationship. Specifically, both parties would benefit from high degrees of automation, efficiency, and standardization from the manufacturing side to support distribution operations across Americas, EMEA, and APAC markets.

For more than two decades, Model N has been embraced by the largest electronic component manufacturers for end-to-end revenue management automation of both front and back-office processes. As a result, the distribution channel has also adopted Model N as a trusted solution to act as a bridge to the manufacturing community for channel management automation that includes everything from design registrations, quoting, pricing, ship-and-debit, inventory levels, point-of-sale processing automation, and incentives like rebates and payments. All of which are modular and effective enough on their own but are also seamlessly connected behind the scenes to increase competitiveness and margin.

Today, even smaller manufacturers can take advantage of how Model N’s standard (and familiar) look and feel can streamline interactions with leading distribution channel partners. This allows manufacturers to focus on their technologies, brands, and services rather than attempting to manually manage channel relationships.

Feeling the pain of the component manufacturers

The No. 1 challenge facing component manufacturers is keeping up with the speed of the market.

- For many electronic component manufacturers – and particularly in the highly commoditized interconnect, passive, and electromechanical (IP&E) component space – the high number of SKUs, and the large volume of small, low-value transactions make it very difficult to engage with channel partners using manual methods. Even if you had the resources to invest in armies of support people, it wouldn’t be humanly possible to keep up and also make a buck.

- The second challenge is getting accurate quotes out quickly to distributors with competitive and correct pricing so as to maximize customer conversion rates and win at higher margins.

- The third challenge is inventory management. Especially in a ship-and-debit environment, manufacturers must possess accurate and up-to-date inventory data at their fingertips. They also need to be able to process returns and rotations and price protection accurately to avoid overpayments which enhances the supplier/distributor relationship.

To date, some manufacturers have tried to deal with these challenges with a mix of manual processes and home-built solutions. Others have tried to cobble together point solutions from different vendors. Add in additional tech stacks from mergers and acquisitions, all of this can really weigh down your agility in the market.

In the meantime, distributors want quotes, and the resultant debits and claims executed ASAP. If you don’t pay your distributors quickly because of inefficiencies in your processes, you can lose their trust – as well as the coordination and cooperation you need from them when trying to accelerate growth through the channel. Rendering payment two quarters later won’t do it.

And without a holistic, integrated solution to manage your channel relationships, things inevitably fall through the cracks. That’s when you lose revenue, profits, or both.

An end-to-end platform enables you to manage complex pricing rules, different contracts, incentives and channel program compliance with your channel partners. Model N Revenue Optimization and Compliance Cloud for High Tech is designed to help component manufacturers confidently execute all aspects of the pricing lifecycle, channel operations, incentive management, and sales execution at speed and scale.

Building an automated bridge between manufacturers and their distributor channel partners

Between 70% to 80% of all high-tech transactions go through distribution channel partners. Delivering a world-class channel management experience for partners is thus an imperative for suppliers and manufacturers in growth mode to stay top of mind.

In my experience, it helps tremendously if channel partners are aligned at the system level.

Over the years, Model N has become the de facto standard by leading component distributors due to how it streamlines the selling process for deal registrations, pricing, quotes, contracts, incentives such as rebates, and channel data management. Because of this, distributors are much more likely to want to partner with suppliers and manufacturers who are on the same platform – the Model N Revenue Optimization and Compliance Cloud. It gives them instant access to do all of these activities without having to be in a swivel chair, logging in to different platforms to make a sale.

I have personally purchased Model N when I was leading channel sales at Kyocera AVX because it bridges the gap between front-office and back-office processes and services as the commercial system of record for all revenue execution and channel automation activities.

In effect, Model N acts as a bridge between manufacturers and distributors, automating many aspects of the relationship, and giving all parties transparency into deals and transactions and payments that avoids the back-and-forth communications that can ensue if trying to manage the relationship manually or if depending on disparate systems.

I’ve been on the sell side of the semiconductor and electronic component industry for 32 years. In my experience, Model N helps drive profitable growth for manufacturers and ensures commercial compliance across the channel.

Keeping up with world-class distributors

The top electronics distributors can help you break into growth from new markets, geographies or technologies, you have to do your share of the heavy lifting in the partnership. Leading distributors like Arrow and Avnet, Future and TTI are huge multinationals with thousands of sales reps and engineers spread across the world. Their customers will want quotes, debits, and design registrations. They will want their debit claim or rebate dollars and they will look to get these things done in a timely manner.

Moving to the Model N platform helps manufacturers enormously by standardizing the way they communicate and interact with these giants of the high-tech distribution world. Otherwise, as a supplier or manufacturer, you wouldn’t have enough customer service, quotes, or design registration employees to handle the volume. Automation is the key. Otherwise, your distributors could bury you with the thousands and thousands of requests they’re going to send your way.

With Model N, you’ll be able to respond to quotes faster, and more accurately – that is, at the right price to convert quotes to sales so you don’t leave any money on the table. This will boost revenues as well as profits – all while you grow through the channel at rates that would be impossible to achieve on your own.

To learn more about how to partner with high-tech distributors to grow your small to medium component manufacturing company, participate in our interactive webinar, “What Distributors Really Want from High Tech Manufacturers.”